1

/

of

6

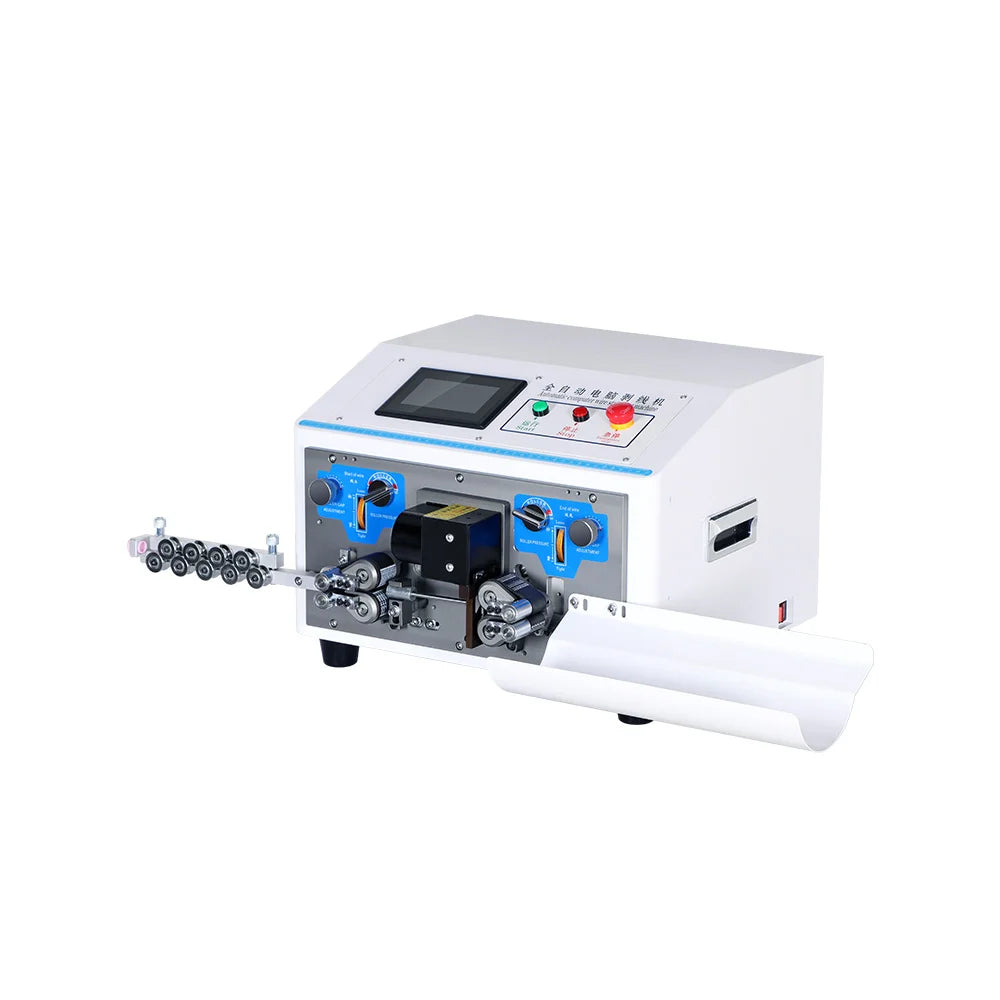

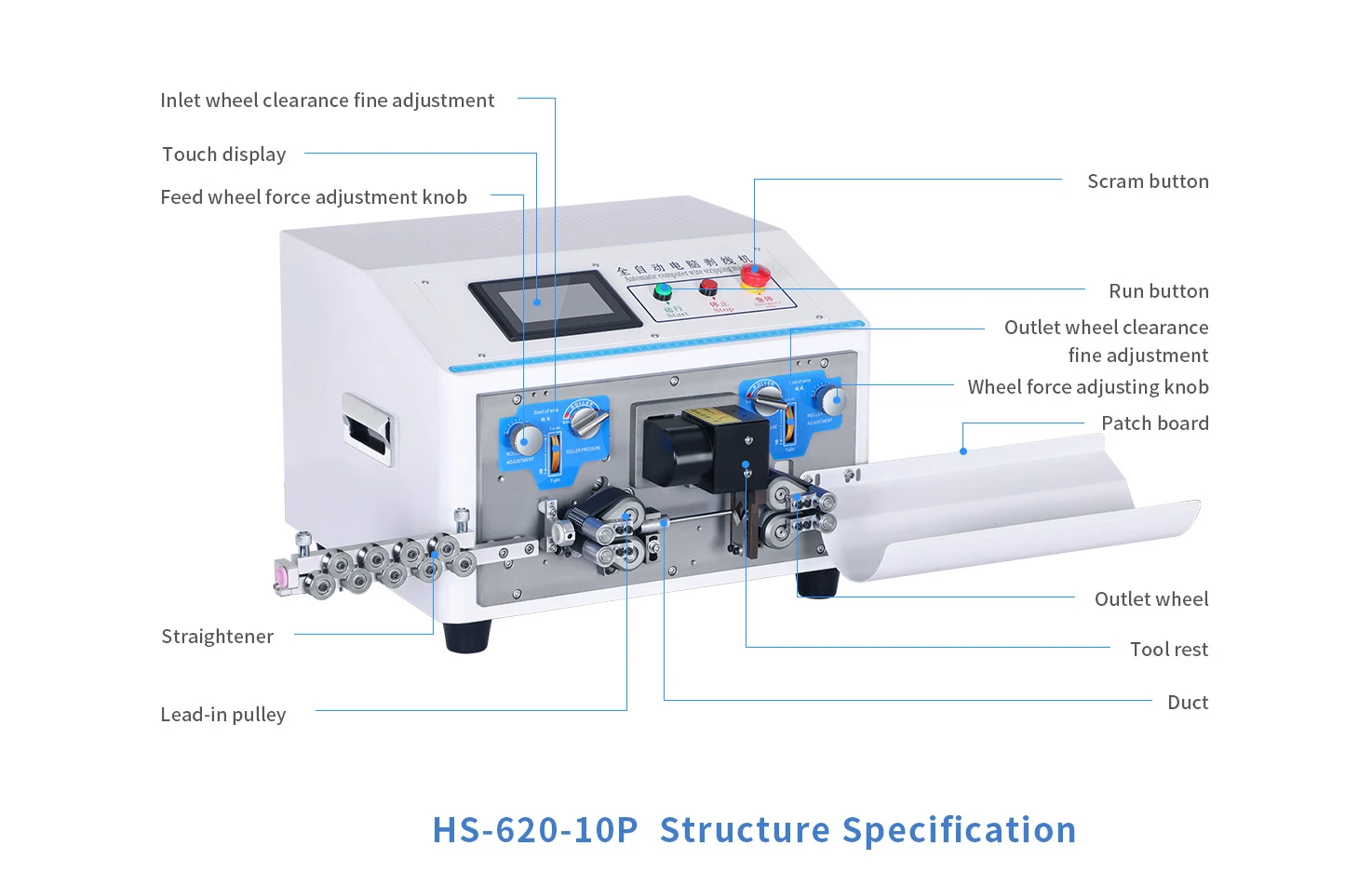

Factory Direct Sales 800W HS-620-10P Wire Stripping Cutting Machine Wire Stripper Machine for 0.1-10 Mm² Wire Square

Factory Direct Sales 800W HS-620-10P Wire Stripping Cutting Machine Wire Stripper Machine for 0.1-10 Mm² Wire Square

Regular price

$983.00

Regular price

$983.00

Sale price

$983.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

In stock

|

Model

|

HS-620-10P

|

|

Size

|

420*297*345mm

|

|

Weight

|

28kg

|

|

Power supply

|

AC175V锛�250≤50/60HZ

|

|

Power

|

120-220W

|

|

Productivity

|

3000-5000pcs/h

|

|

Peeling length

|

Head 0.1-50mm, Tail 0.1-30mm

|

|

Display method

|

4.3-inch touch screen

|

|

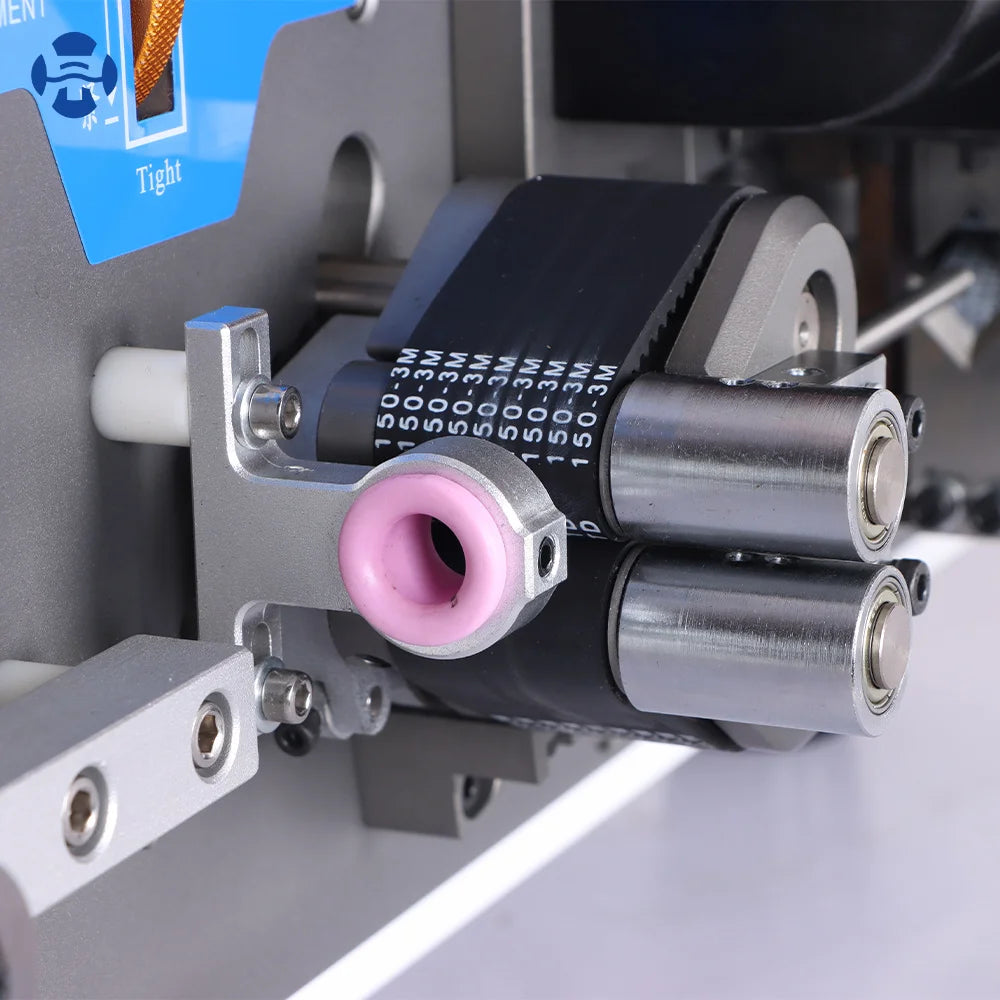

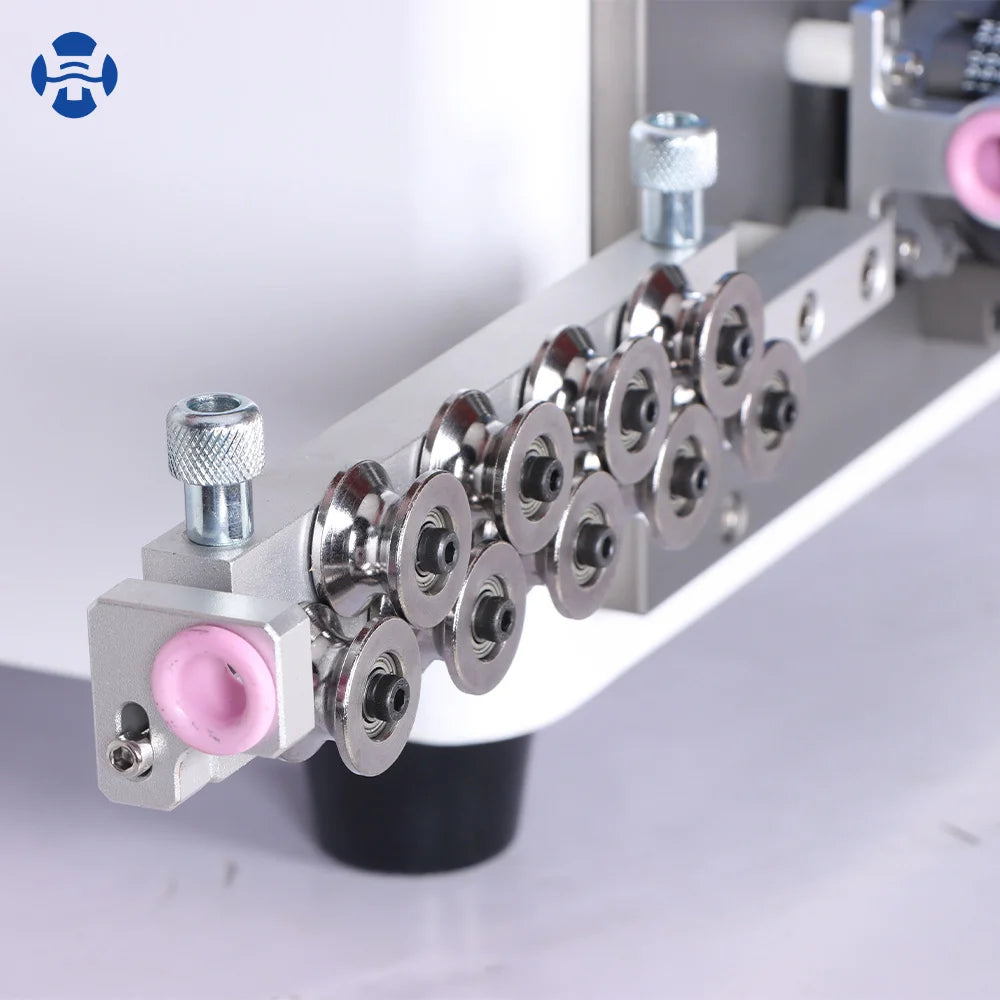

Pipe inner diameter

|

1.5-9mm

|

|

Applicable wire square

|

0.1锛�10 mm²

|

|

Cuttting length

|

1-99999mm

|

|

Cutting tolerance

|

±0.002mm*L

|

|

Peeling tolerance

|

±0.2mm

|

|

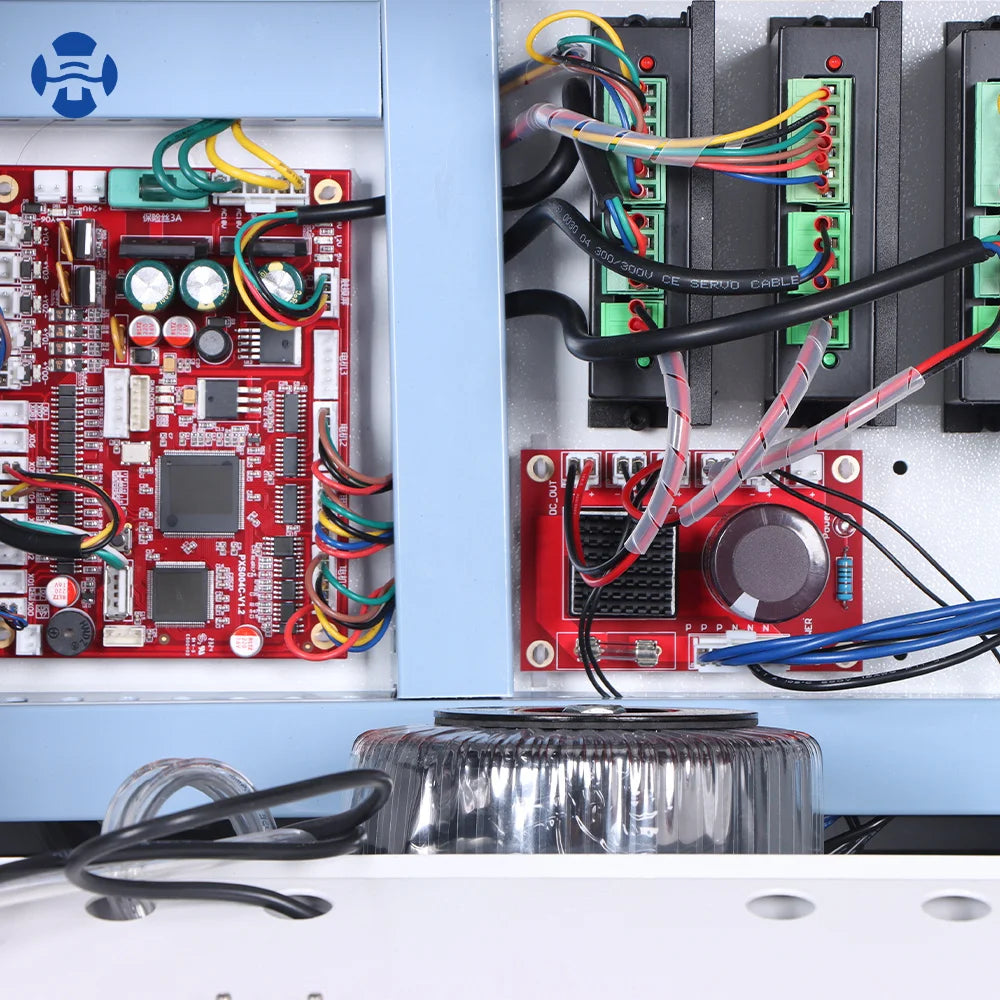

Drive method

|

4 rounds servo motor

|

|

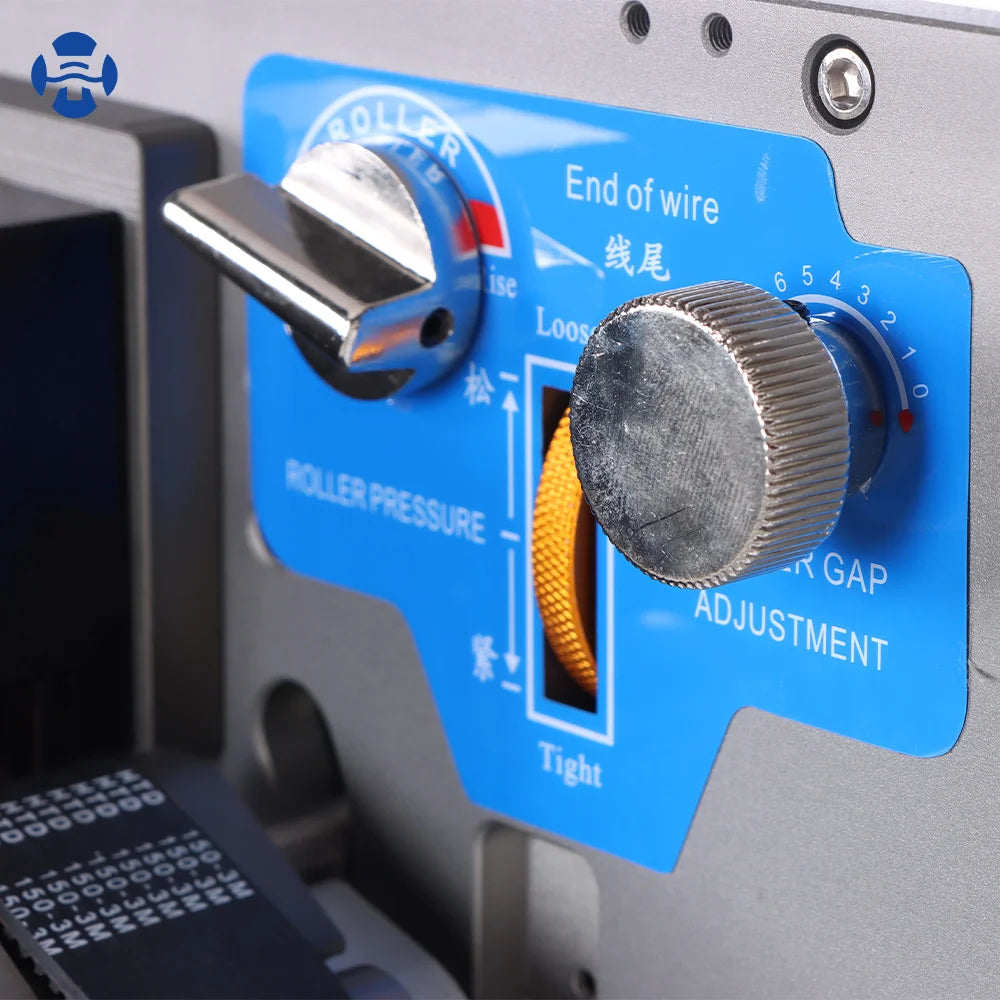

Speed adjustment gear

|

0-9

|

|

Tool material

|

Tungsten steel/imported high-speed steel

|

Product Application

1. High-precision processing: It can precisely control the cutting and stripping lengths according to preset parameters, with

extremely small errors and millimeter-level deviations. Moreover, it can automatically adjust the tool pressure and cutting depth

according to the wire diameter, ensuring high precision for both thin and thick cables and guaranteeing high-quality connections.

2. High-efficiency production capacity: It has a high degree of automation, can work continuously and quickly, and can process a

quantity of wires that is several times that of manual work. The rapid mold change system reduces equipment adjustment time and

improves the output and quality per unit time.

3. Simple and flexible operation: The operation interface is intuitive and easy to master after training. Parameters can be

conveniently input. There are multiple working modes, which can be set for single wire cutting or simultaneous wire cutting and

stripping. It can also set different parameters for different batches to meet diverse production requirements.

extremely small errors and millimeter-level deviations. Moreover, it can automatically adjust the tool pressure and cutting depth

according to the wire diameter, ensuring high precision for both thin and thick cables and guaranteeing high-quality connections.

2. High-efficiency production capacity: It has a high degree of automation, can work continuously and quickly, and can process a

quantity of wires that is several times that of manual work. The rapid mold change system reduces equipment adjustment time and

improves the output and quality per unit time.

3. Simple and flexible operation: The operation interface is intuitive and easy to master after training. Parameters can be

conveniently input. There are multiple working modes, which can be set for single wire cutting or simultaneous wire cutting and

stripping. It can also set different parameters for different batches to meet diverse production requirements.

Our products are mainly used in new energy electric vehicle wiring harness processing, charging gun and charging pile processing,aerospace, data transmission, medical equipment, industrial electronics, home appliances and other fields.

SKU:

View full details